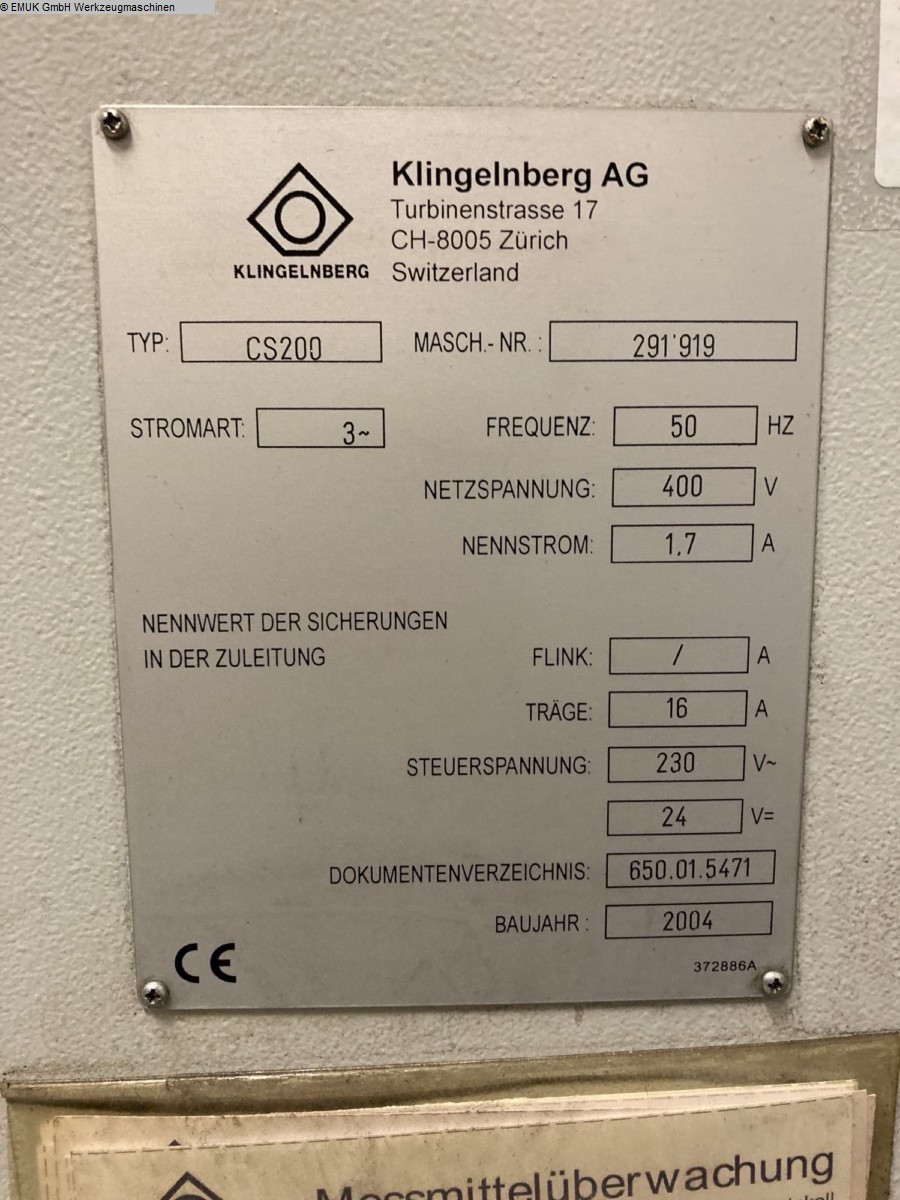

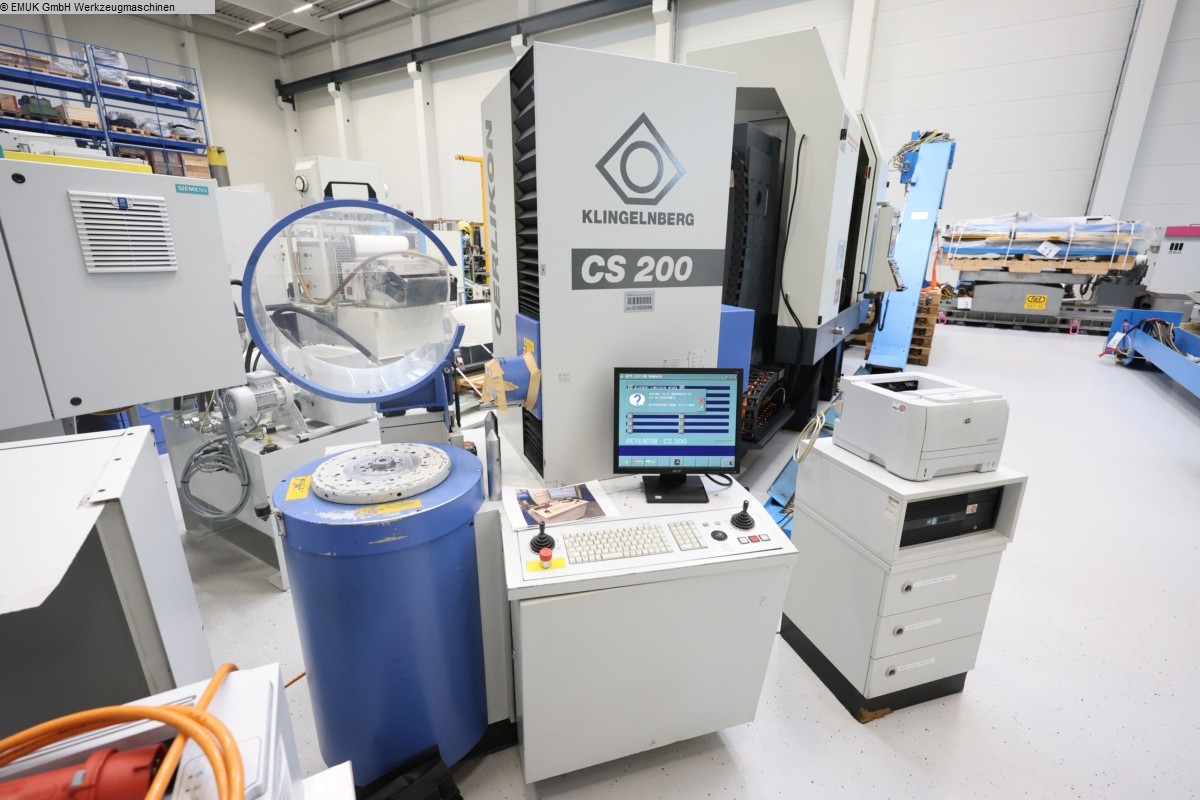

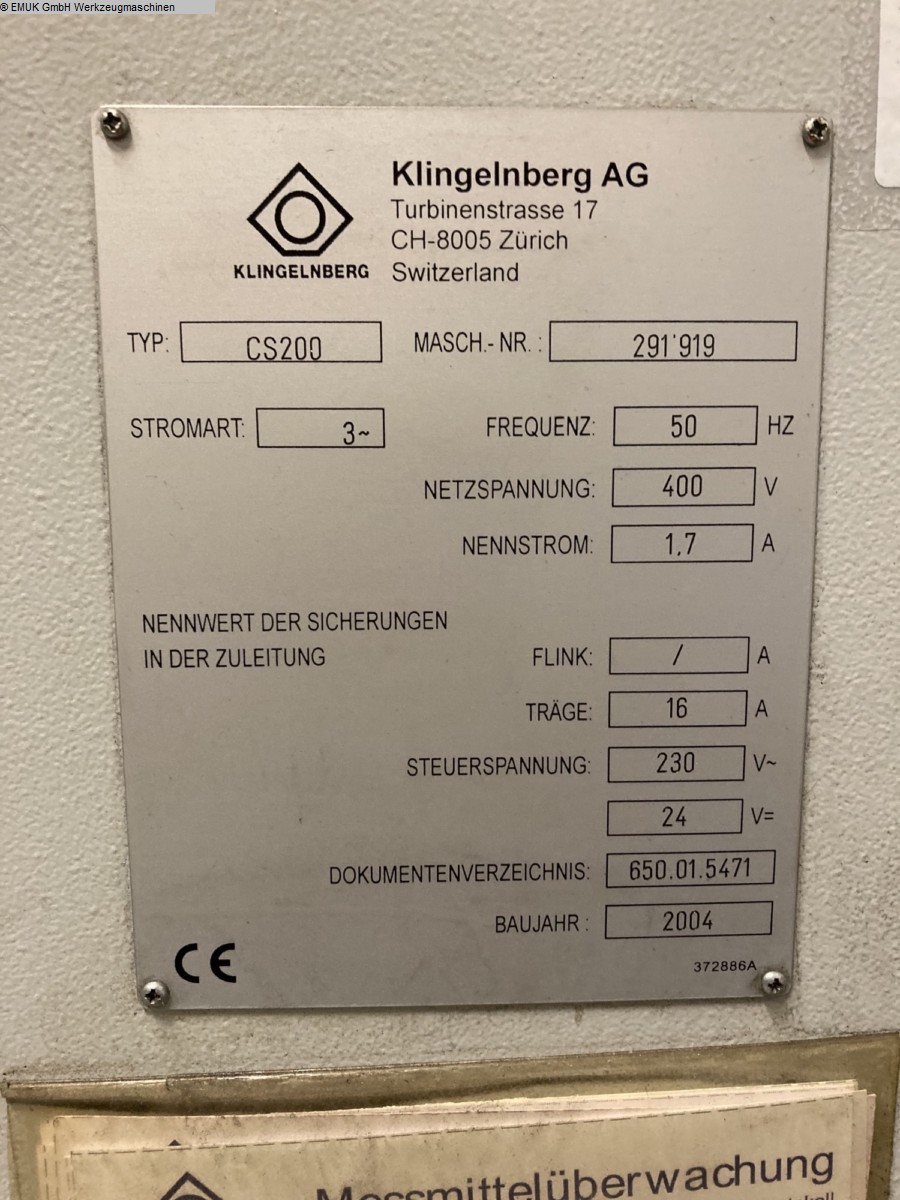

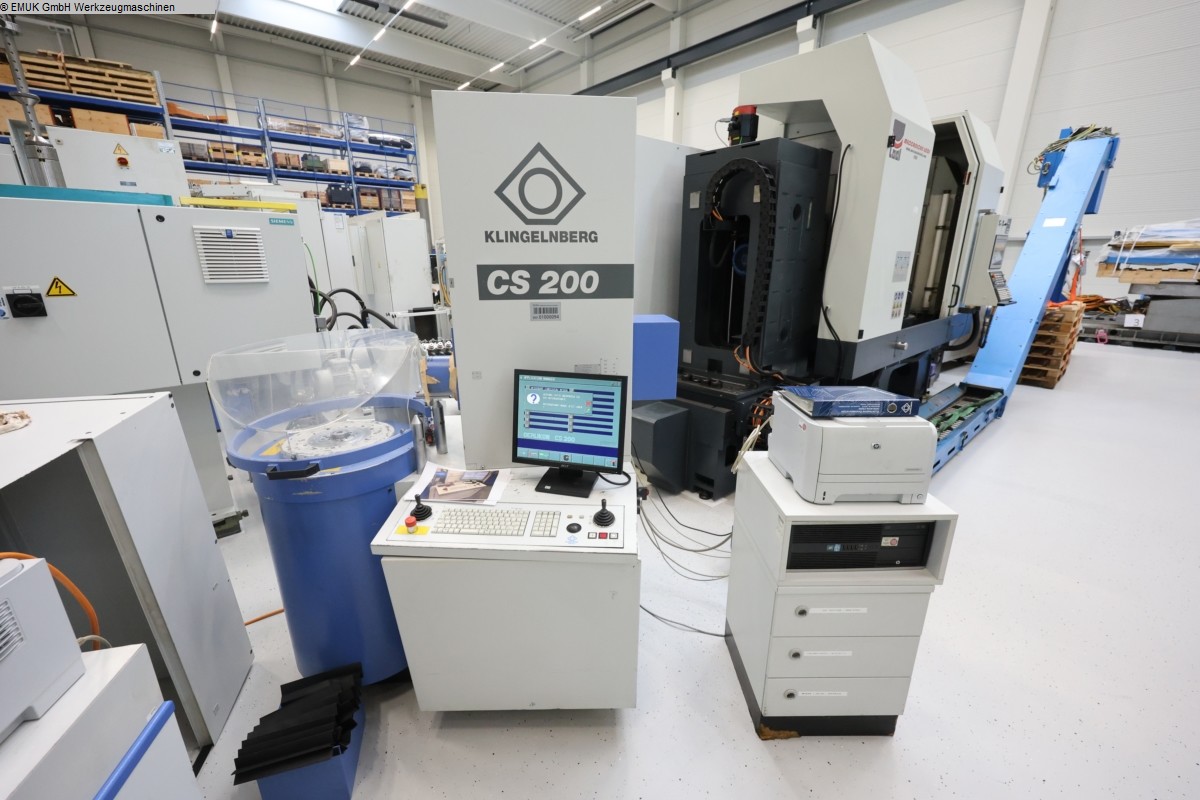

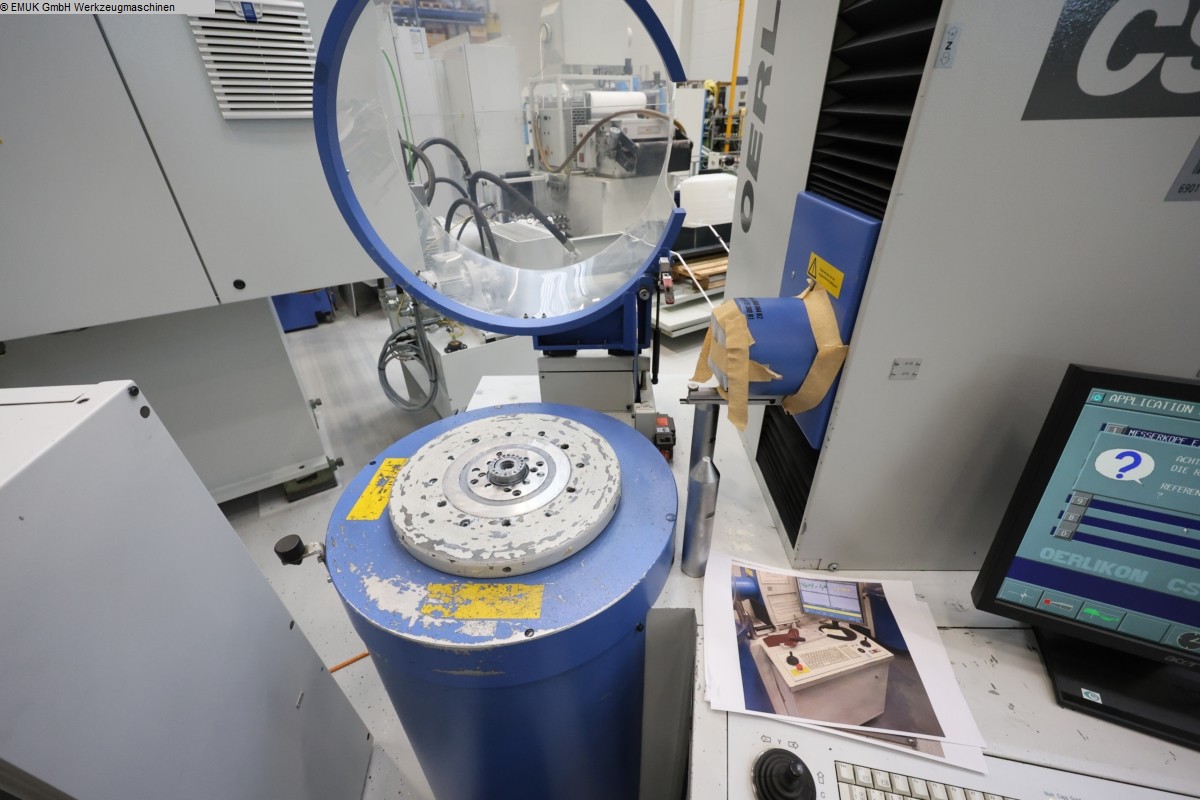

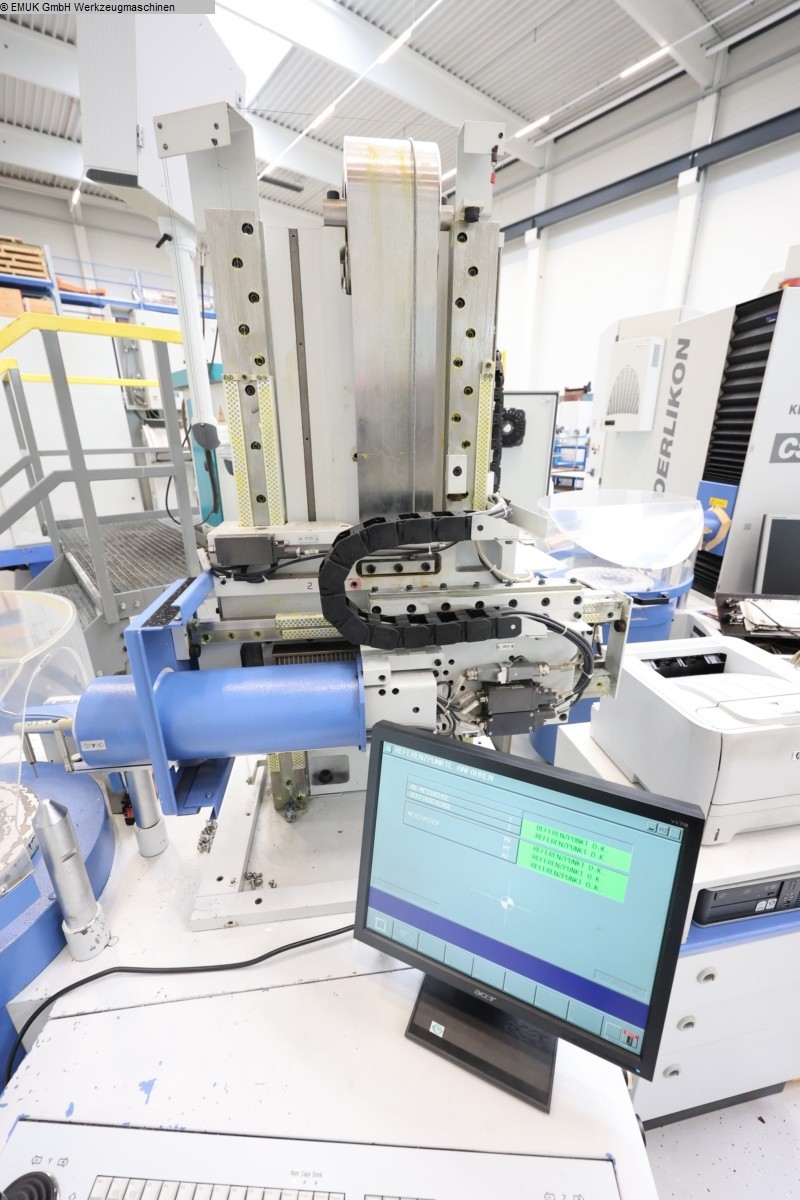

KLINGELNBERG-OERLIKON CS 200

In the manufacturing process for spiral-toothed bevel gears, the quality of the

gear cutting gear cutting tools used plays a decisive role. Particularly in

high gear cutting quality and a long service life can only be achieved with

precisely can only be achieved with precisely adjusted cutterheads.

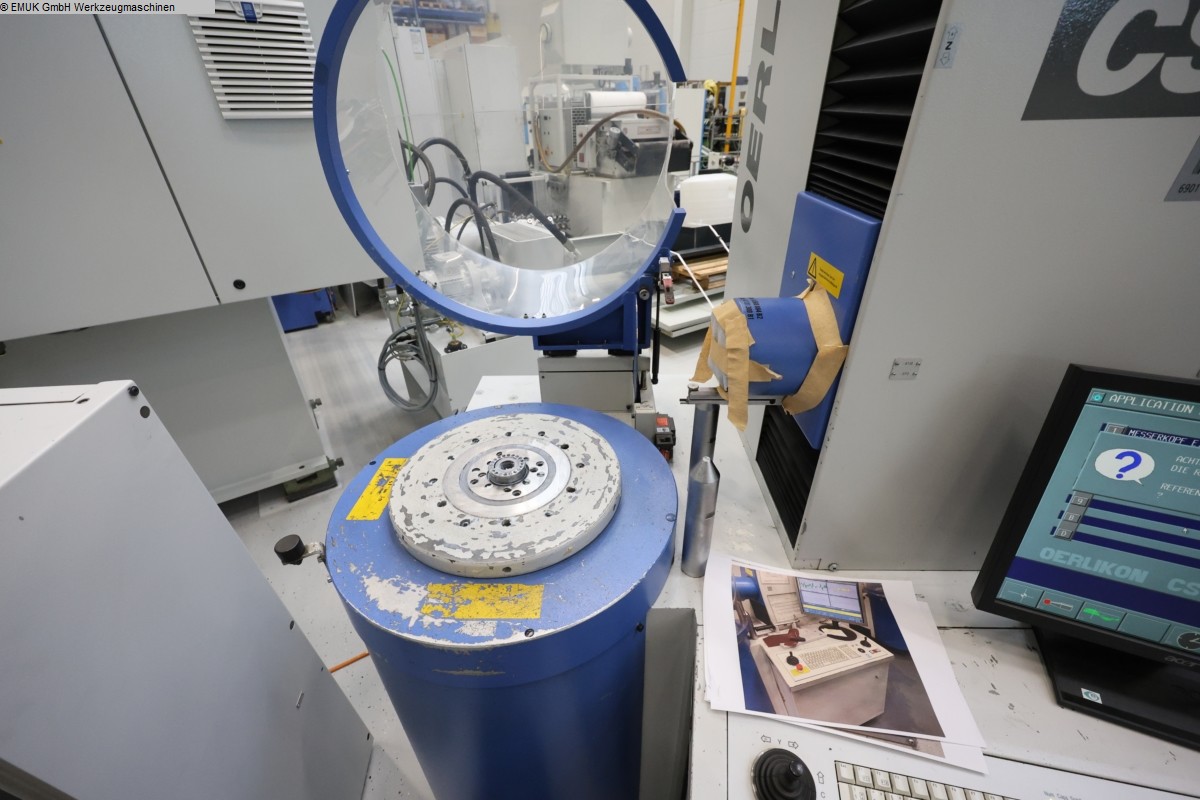

The Oerlikon cutterhead setting and testing device CS 200 enables quick and

easy setting of the individual knives and simple adjustment of the individual

knives, it checks the position and documents the measurement results. The

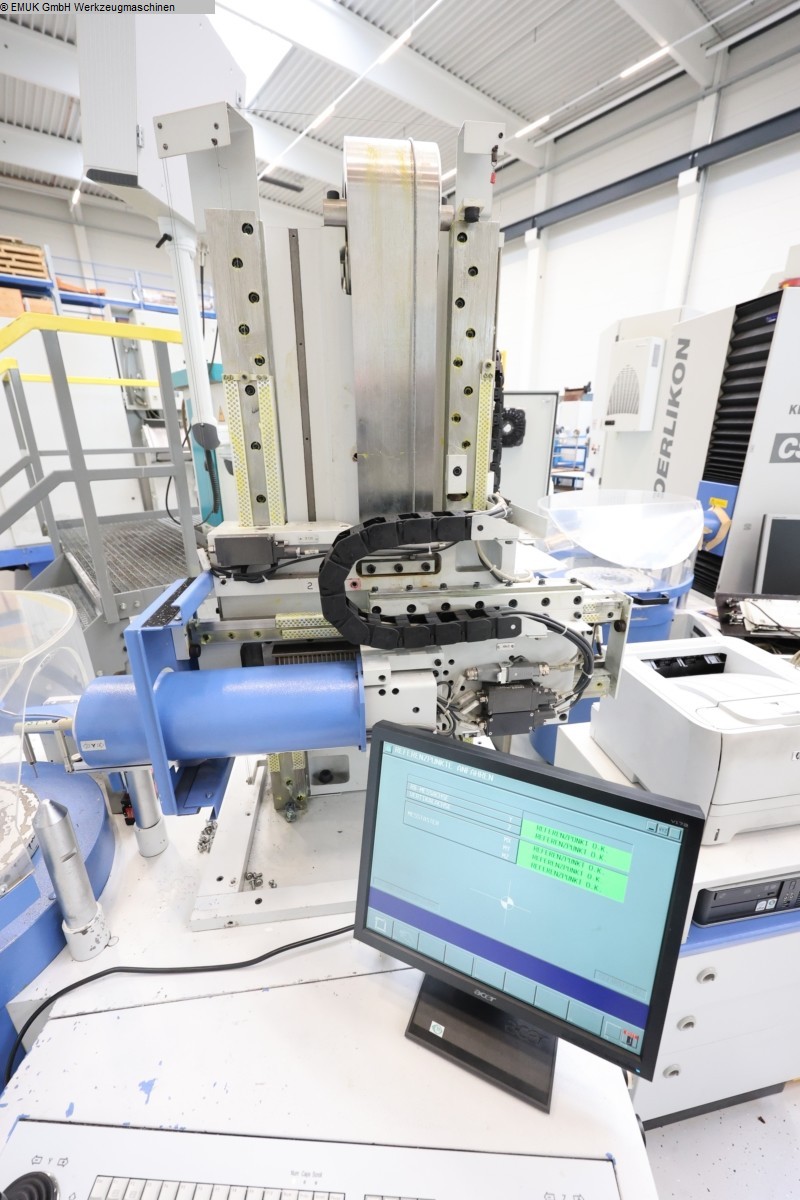

measuring sequence on the CNC-controlled testing device is partially automated:

The individual actions for carrying out the actions for carrying out the

sequence are displayed on the screen via the operator guidance. The positioning

of the individual knives in the cutter head and the height of the knife tips is

largely automatic thanks to a special sequence and is simultaneously documented

by means of a run-out diagram. A subsequent measuring sequence checks the

radial position of the inner and outer cutting edges of all knives in the

cutterhead. If individual test parameters on the knives do not correspond to the

the tolerance specifications, this can be individually repositioned. The

combination of semi-automated setting sequence, operator-guided set-up actions

and automatic operator-guided set-up actions and automatic measuring sequence,

cutterheads can be can be set conveniently, quickly and with high precision.

Operator-guided setting and test sequence

- Graphic display of the cutter head design and the measurement results with

tolerance check

- Instructions for the operator in plain text Instructions for the operator in

plain text (without coded information)

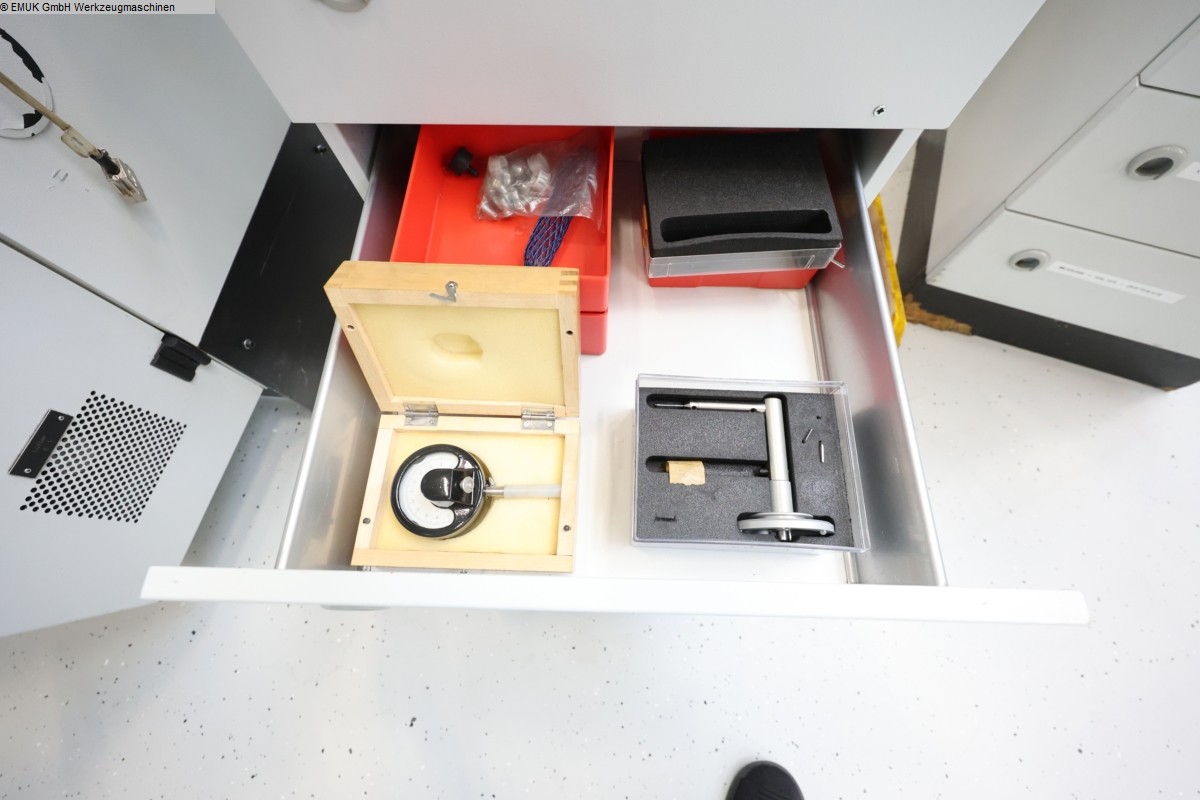

- Simple assignment of the measurement results to the knives

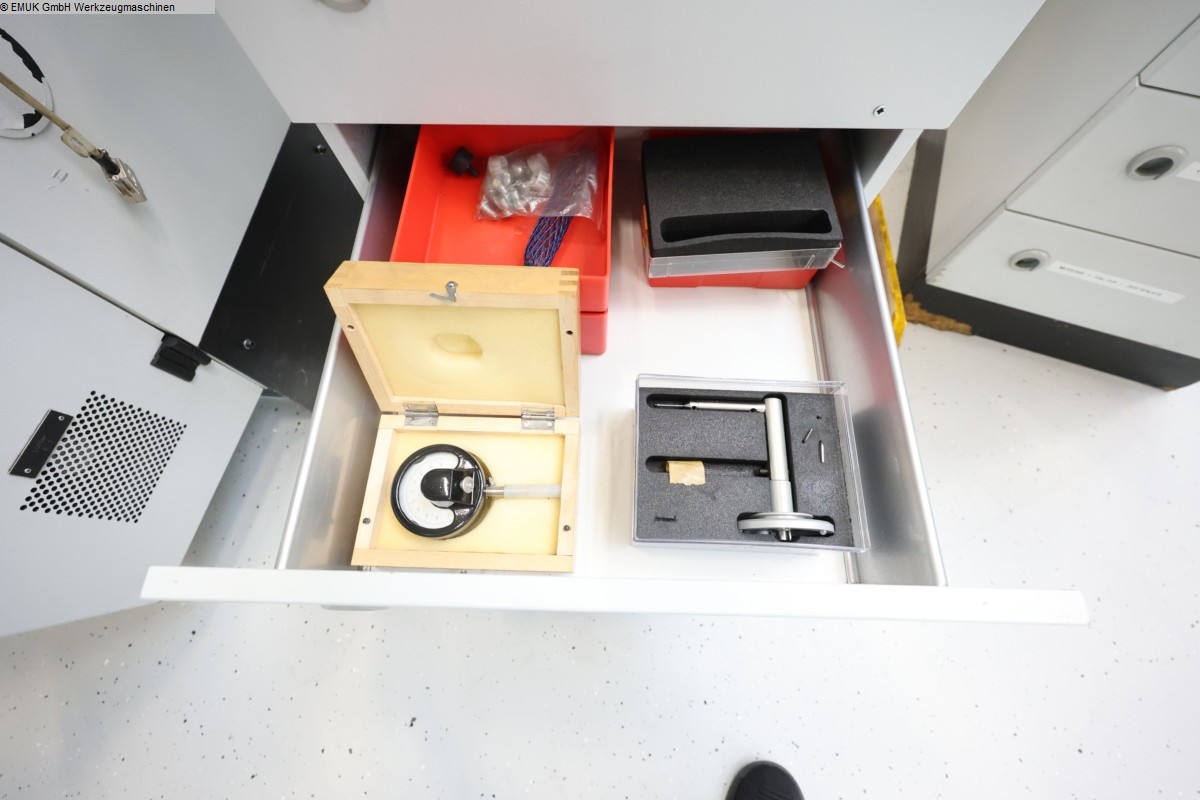

- Documentation of the setting and measurement results via printer- Setting and

test sequence suitable for ARCON®, RSR, Spirapid, SPIRON®, TRI-AC® types

- Interface for neutral data