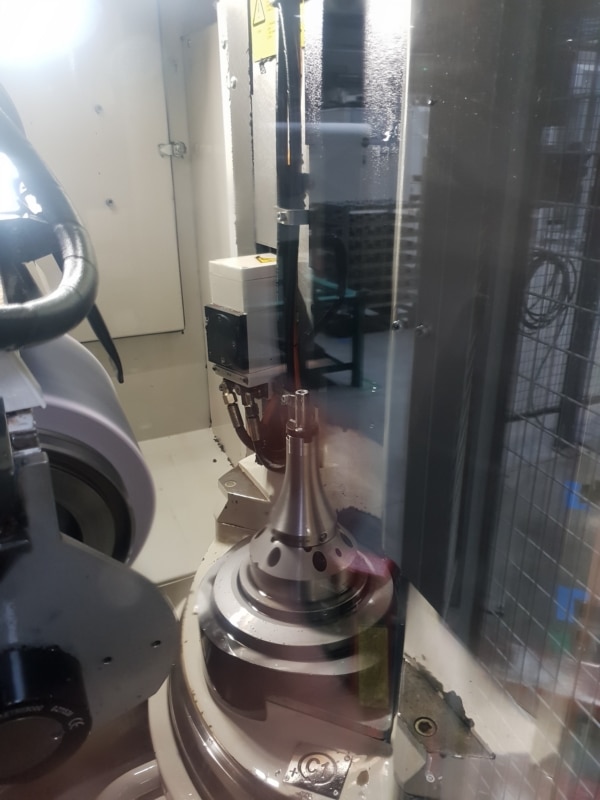

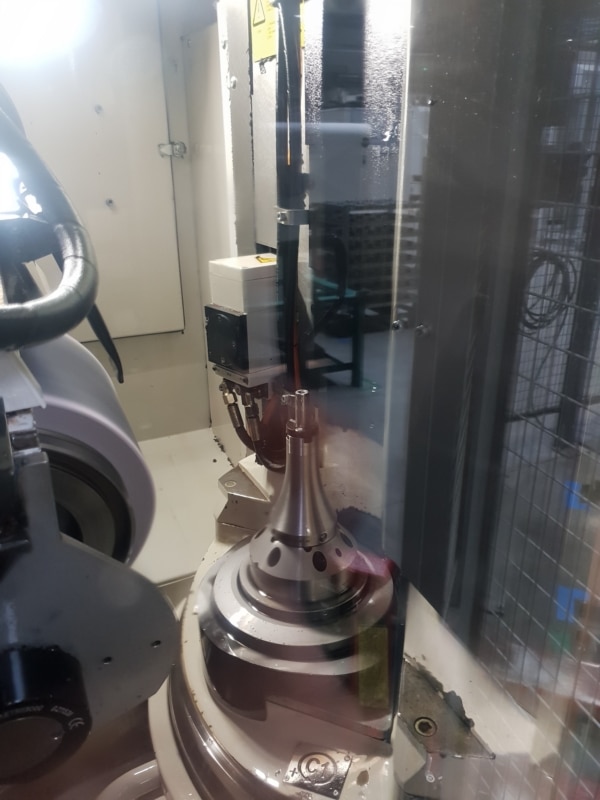

REISHAUER RZ 150

with KUKA robot loading system

TWIN-SPINDLE TECHNOLOGY

The twin-spindle concept significantly shortens the cycle time and guarantees

the high production output of the Reishauer generating grinding machine. During

the grinding of a gear, the previously ground workpiece is unloaded on the

second workpiece spindle workpiece is unloaded, the next gear to be ground is

loaded and centred.

REISHAUER GEAR HOBBING MODULE

The generating module coordinates the complex axis movements of the generating

grinding process and generates the exact geometry of the workpiece. Reishauer

relies exclusively on the hobbing module developed in-house. This makes us more

precise and continue to set the technological standards.

REVOLUTIONARY PROCESSES

Thanks to the targeted further development of the grinding process, Reishauer

has been the technology leadership in the hard fine machining of gears for

decades gears. One example of this is grinding with a cutting speed of 100

metres per second, polishing grinding and topological grinding.

Equipment/accessories:

- Turret with 2 workpiece spindles and dressing unit

- Counter holder

- 3 workpiece clamping devices

- Centre unit with sensor

- Hoffmann filter unit

- 1 flange with grinding disc

- Kuka robot

- Safety devices for transport

- documentation