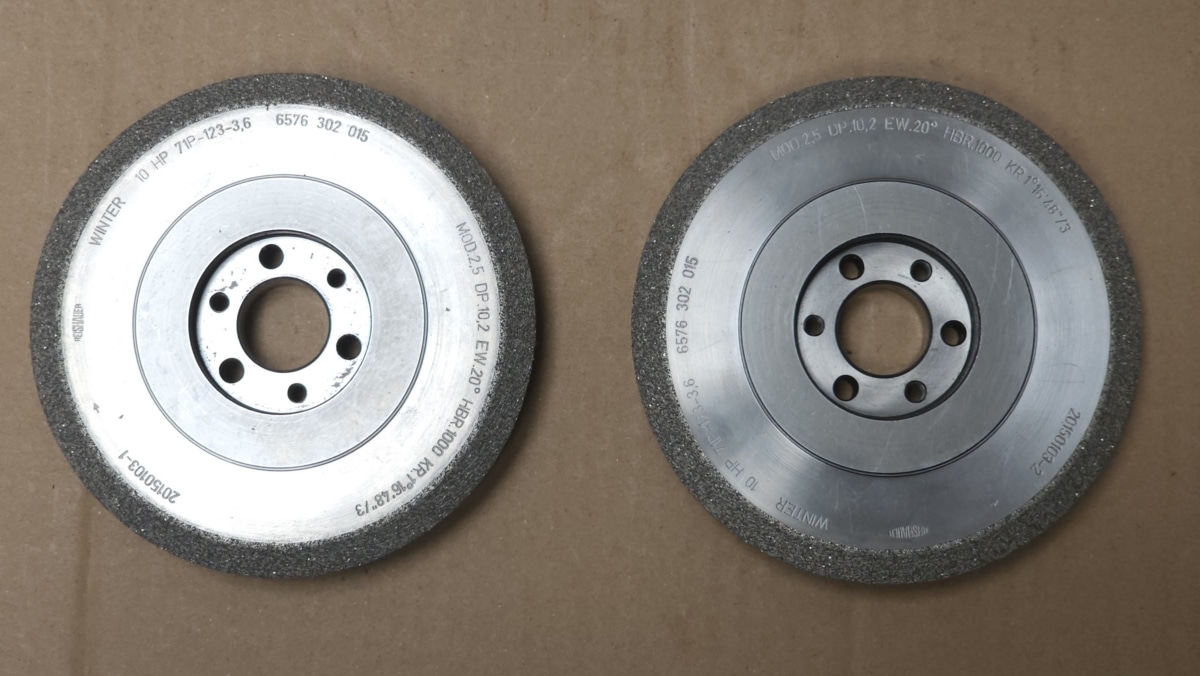

WINTER Abrichtscheibe Modul 2,5

Winter System Reishauer - Diamant Abrichtscheibe Modul 2,5 - DP 10,2 - EW 20° -

HBR=1000 - ID-Nr. 69631_01

The classic process for dressing grinding wheels

grinding wheels in all areas of mass production

the workpiece geometry-based profile roller. The

short dressing times due to radial plunging of the grinding wheel

grinding wheel into the dressing roll help to achieve

fast and reproducible workpiece dressing.

reproducible workpiece application. All conventional abrasives and, in special

applications

hard abrasives in special applications.

For filigree workpiece geometries or materials that are difficult to cut

materials that are difficult to cut, continuous

CD dressing (continuous dressing) is often used.

- Thread

- Turbine blades

- Bearing seats

- Bearing raceways

- valves

- nozzle needles

- shear blades

- gear wheels

- Twist-free surfaces

Translated with DeepL.com (free version)