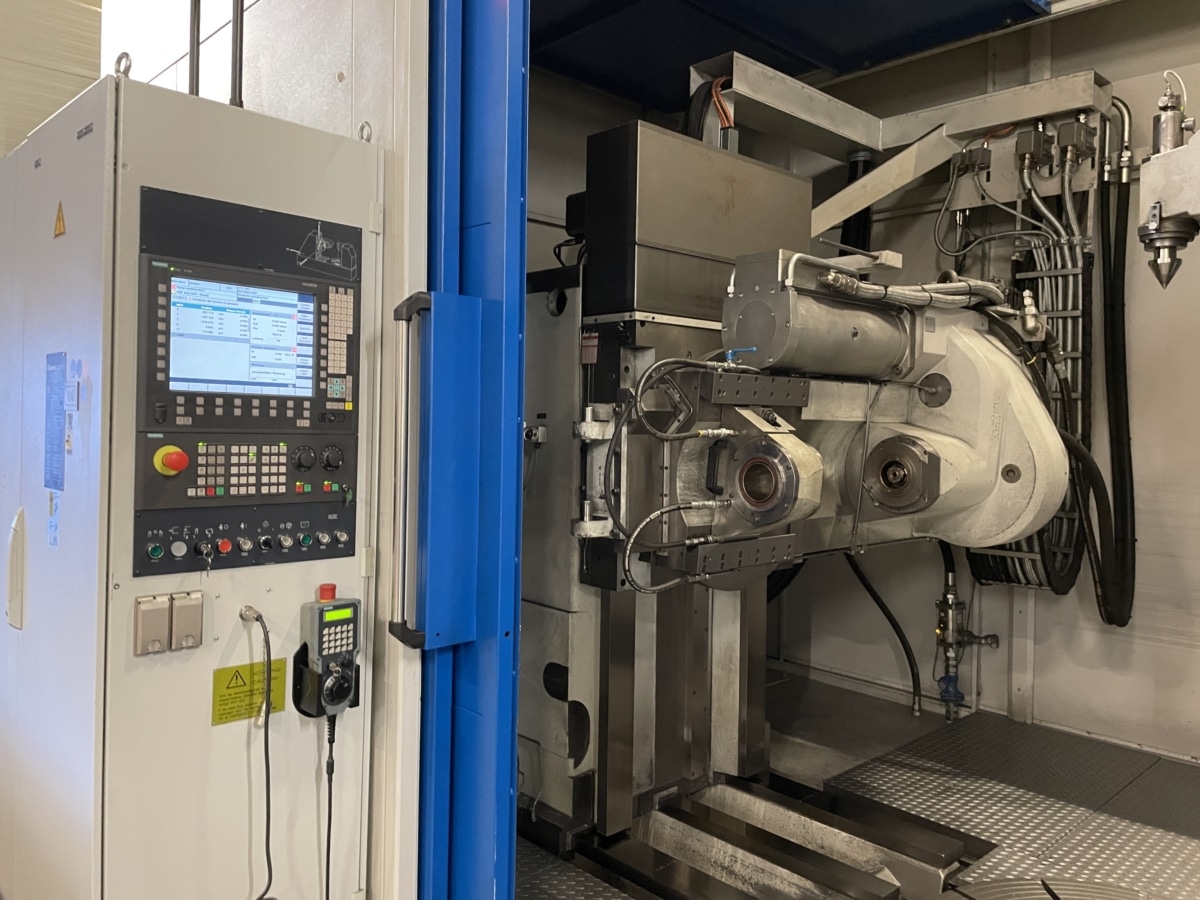

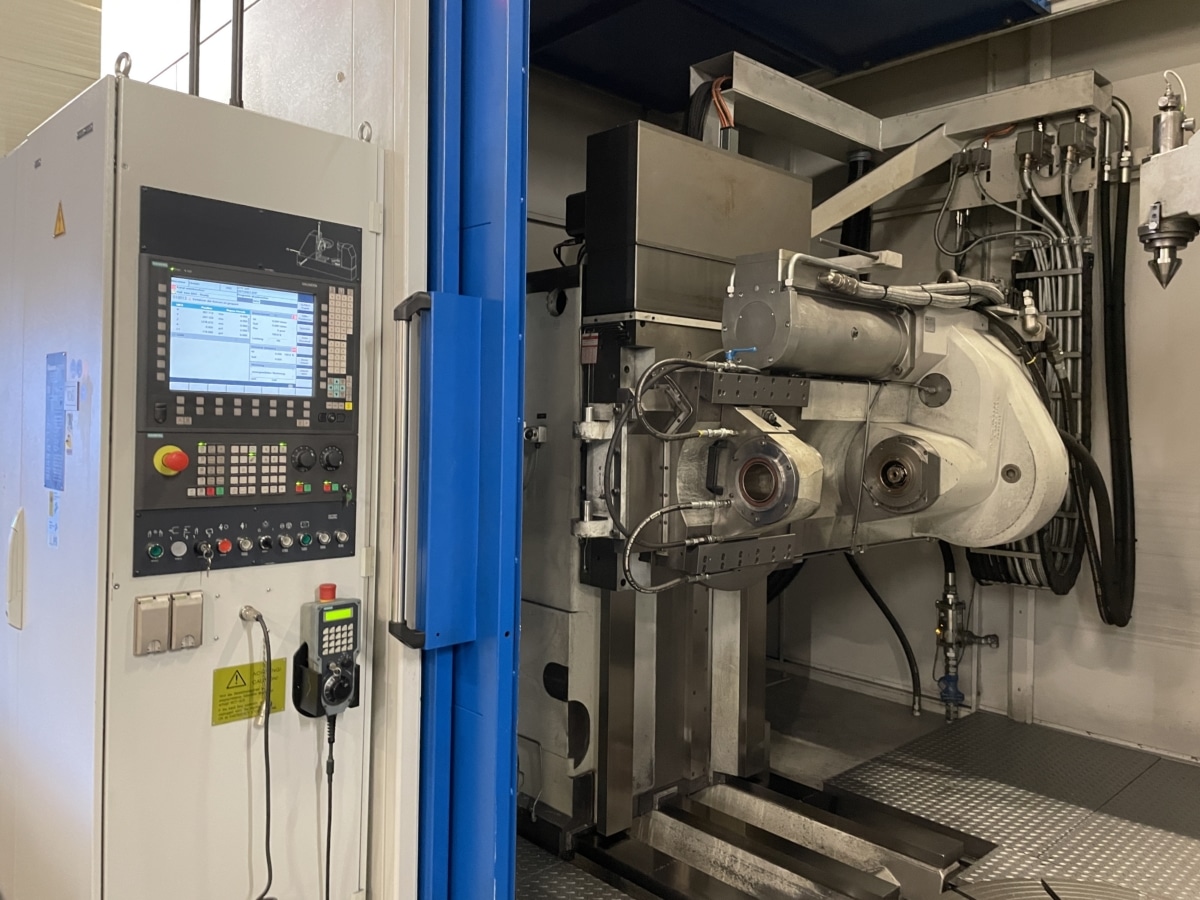

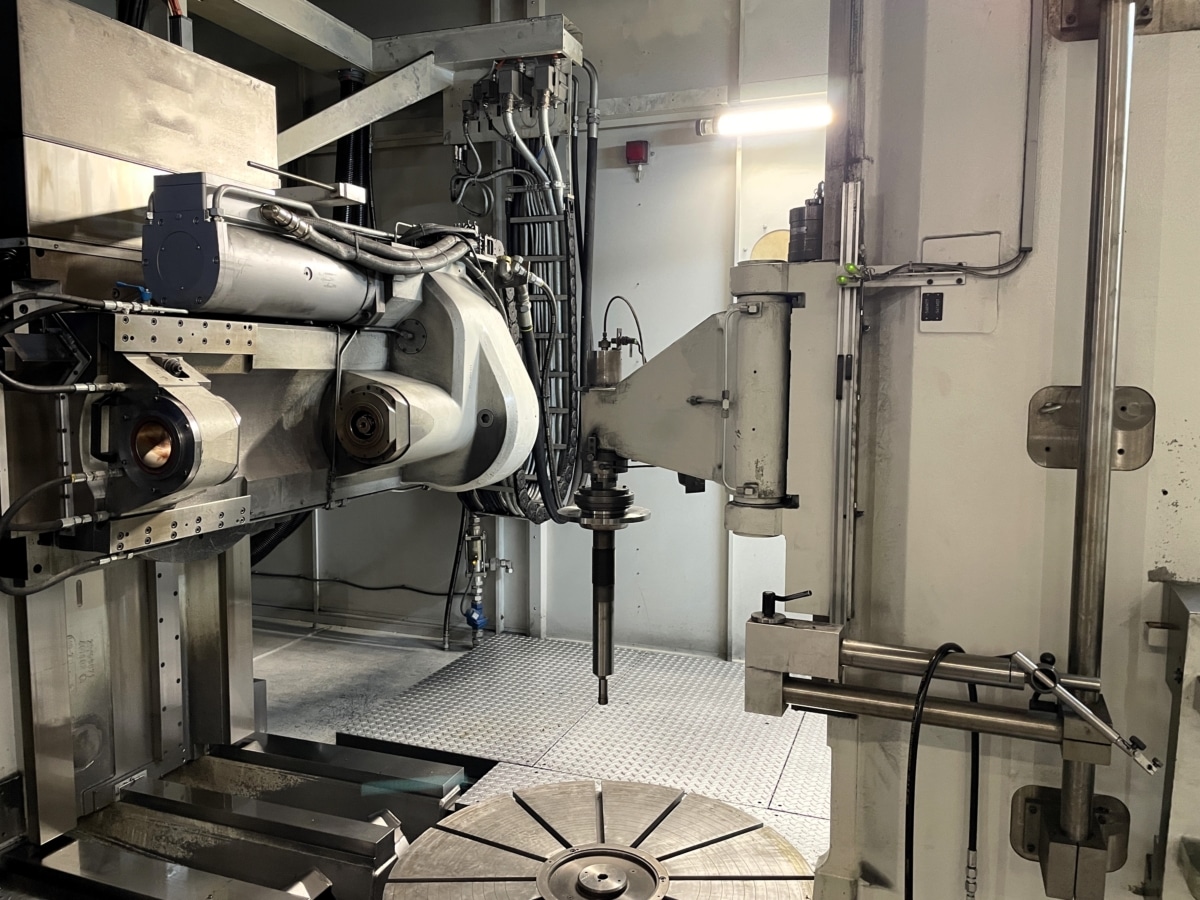

GLEASON- PFAUTER P 1200

Gleason-PFAUTER CNC hobbing machine P 1200 for gear cutting of cylindrical and

worm gears worm gears and all other rolling profiles and shapes that regularly

occur on the cylindrical workpiece circumference.

Remark:

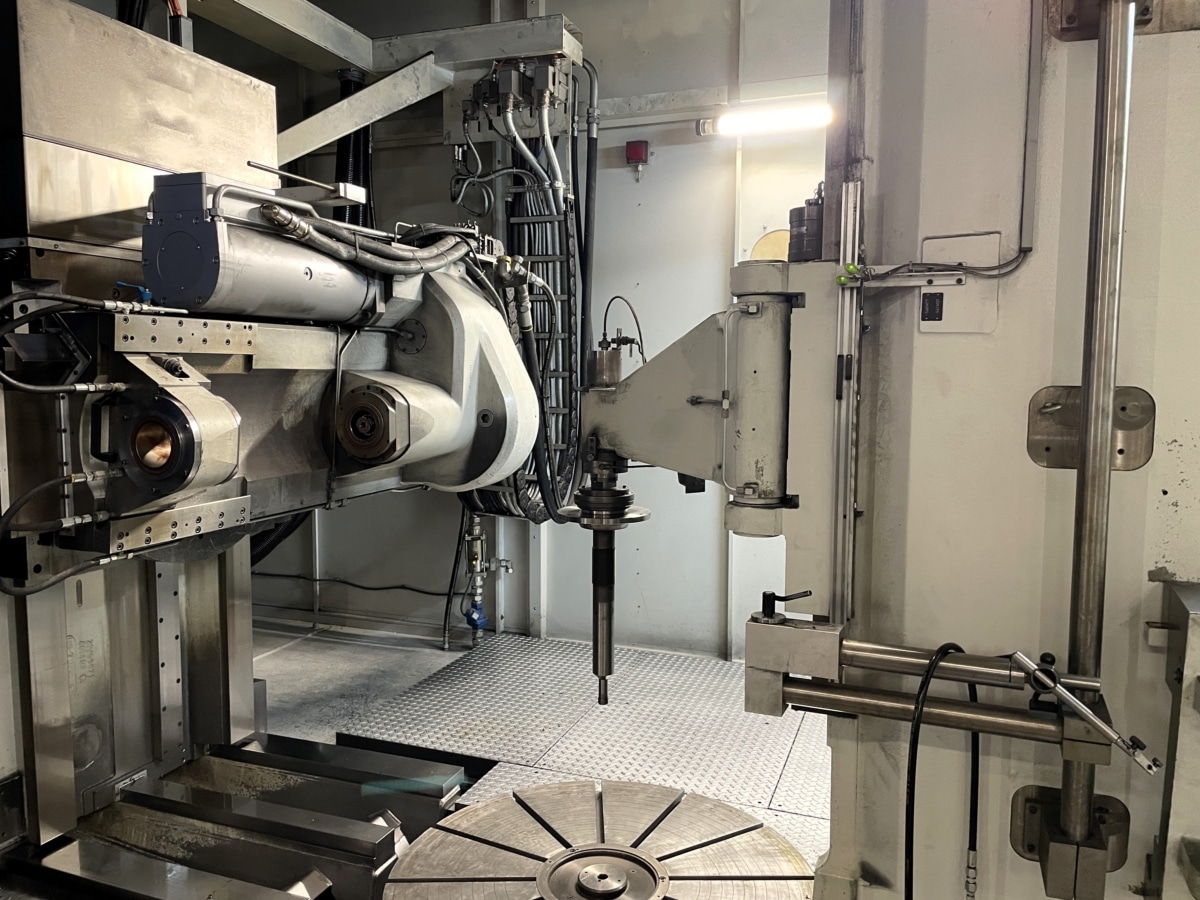

Machine designed for external milling, large milling head M3. Machine with

counter stand.

Scope of equipment:

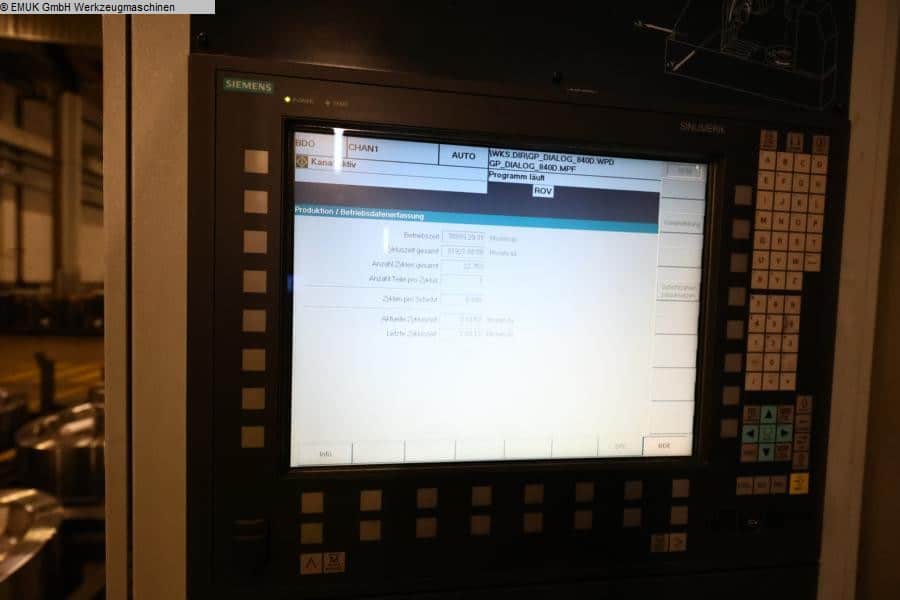

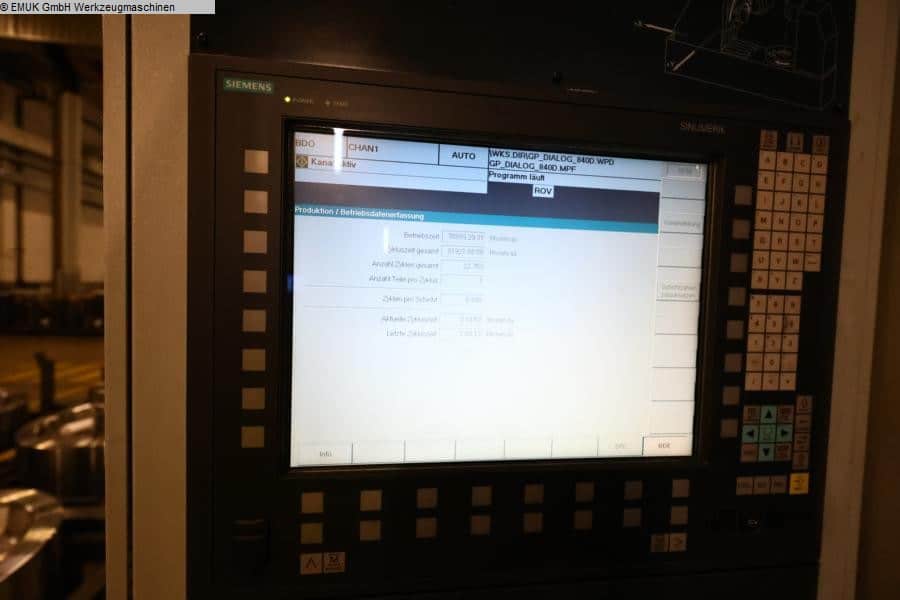

- Basic machine P 1200, Siemens 840D PowerLine (XP)

- Motorised milling head M3

- Special speed series motorised milling head M3

- Extended software for fault diagnosis

- Main stand - raised 1000mm

- Power clamping device

- 2 x fume separator make "3nine" type EMMA

- Chip scraper conveyor

- Set of adjustable wedges

- Switching the machine (dry/wet)

- Dialogue program "Milling in single-part process"

- Magnetic roller

- Special chip separator

- Counterholder sleeve

- Holder for oscillating pressure bell

- Signal light (3-coloured)

- Telephone diagnosis system

- Swivelling counter bearing holder

- Monitoring devices

- Warm-up programme

- Network connection (Ethernet)

- Dialogue program "Saving shifting data"

- Dialogue program "Saving damaged areas"

- 19" flat control panel OP 015A

- Rinsing gun

- Special software Free travelling counterholder

- Intermediate plate 300 mm for raising the counter support position

- Milling arbor 40 mm diameter changed to milling arbor 60 mm

- BDE/MDE interface in the machine control cabinet

- Oil separation systems 3nine System EMMA

Working range and technical data:

- Nominal workpiece diameter... 1.200 mm

- Hobbing approx... . . . . .....25 mm

- Tooth moulding approx. . . . ....35 mm

Guide values depending on the respective machining task.

- Smallest/largest distance between milling cutter and workpiece axis 100/750 mm

- Largest axial slide path... 1.000 mm (special design)

- Largest clampable hob cutter - Ø... 450 mm

- Length... 500 mm

- Swivelling range of the milling head... + 30/- 45º

- Cutter arbour taper... HSK-B160 (hollow shank taper according to DIN 69063)

- Largest milling cutter movement... 450 mm

- Table diameter... 1.200 mm

- Table bore - Ø... 300 mm

- Depth... 875 mm

- Maximum table load approx... 15.000 kg

Workpiece:

- Module max. 25 mm (in steel, 600N/mm²),

- Module profile milling max. 35 mm,

- Ø max. 1.200 mm,

Roll milling cutter:

- Head circle Ø max. 450 mm,

- length max. 500 mm, carriage travel: X/Y/Z - 800 / 450 / 1.000 mm,

- Milling head swivelling angle +A/-A: 30/15 degrees,

- Hydraulic unit, made by Parker,