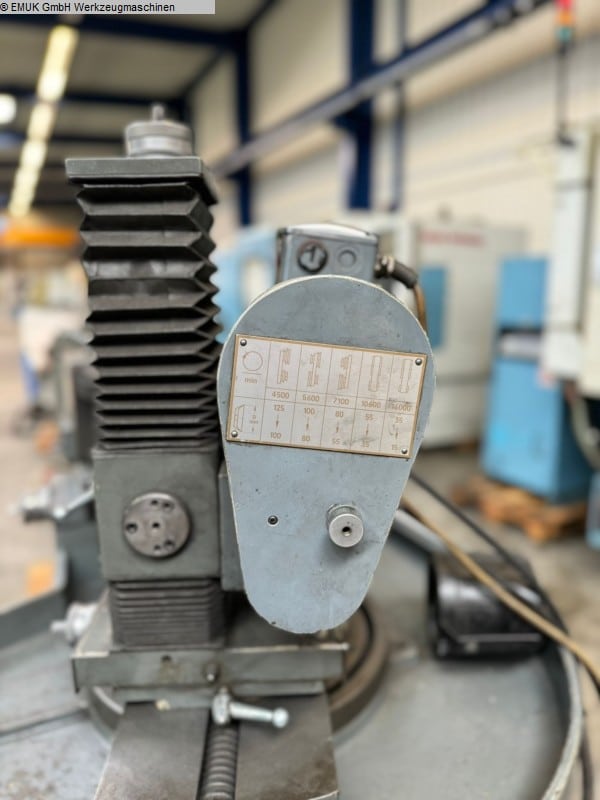

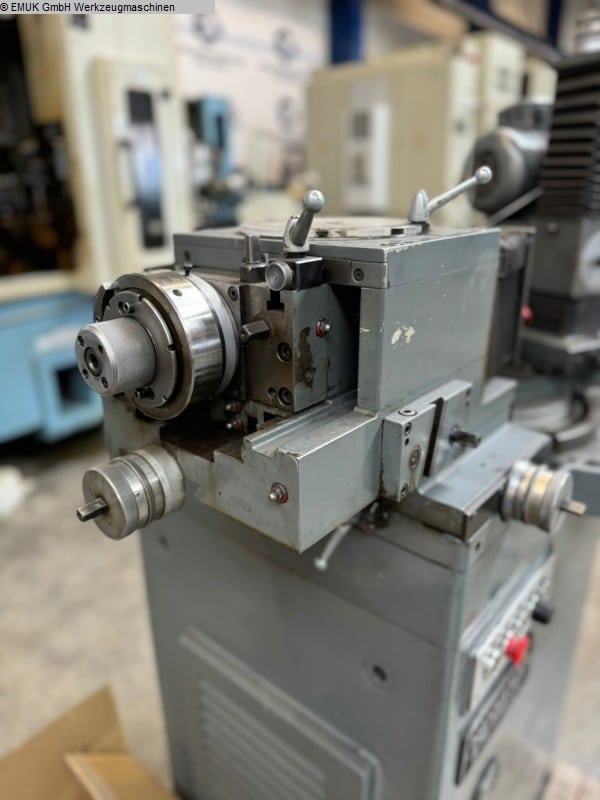

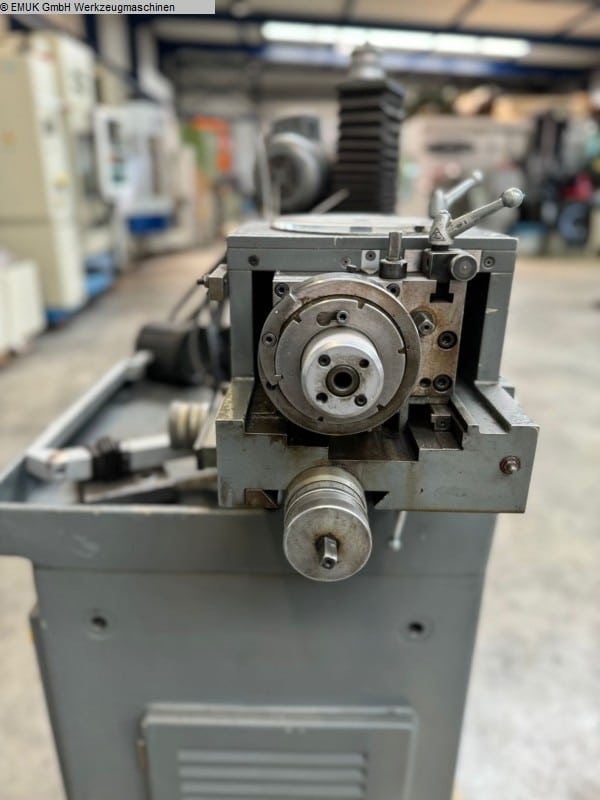

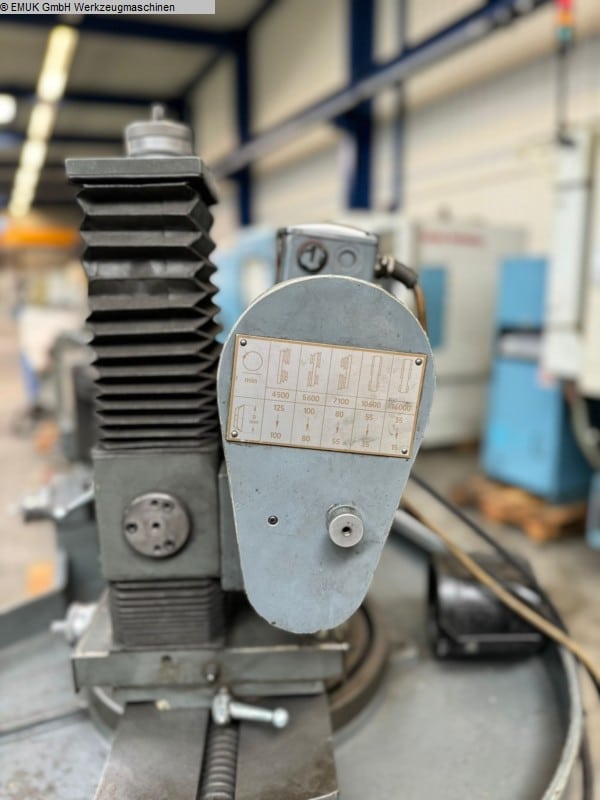

Manufacturer

Hahn&Kolb WS 54

1058-24068

Price on request

Category

Tool and Cutter Grinder

Year of manufacture

1985

Storage location

Malsch

Country of origin

Germany

Delivery time

immediately