WAHLI 9500

with additional worm milling head

TECHNICAL DATA

Machine performance:

Max. Module in stainless steel 2mm

Max. Workpiece diameter with 40 mm Fraser 160 mm

Max. Workpiece length 200 mm

Max. Milling length 140 mm

Max. Cutter diameter 50 mm

Max. Cutter width 60 mm

Max. Cutter shift travel 60 mm

Max. Inclination angle of the milled teeth +/- 45 degrees

Possible number of milled teeth 2 to 1000

Max. Centre distance between milling cutter and workpiece 110 mm

Max. Max. radial feed 100 mm

Milling cutter speed 20 to 4000 min-1

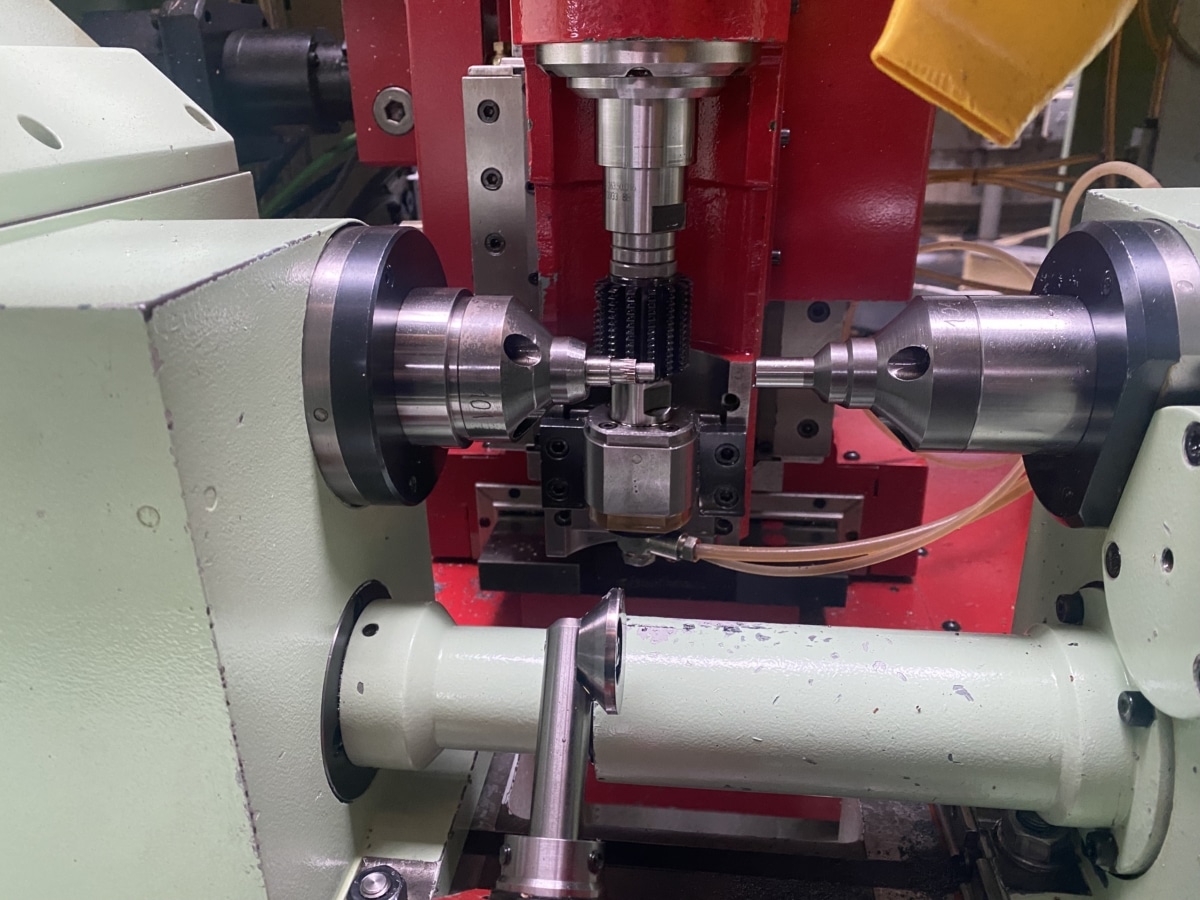

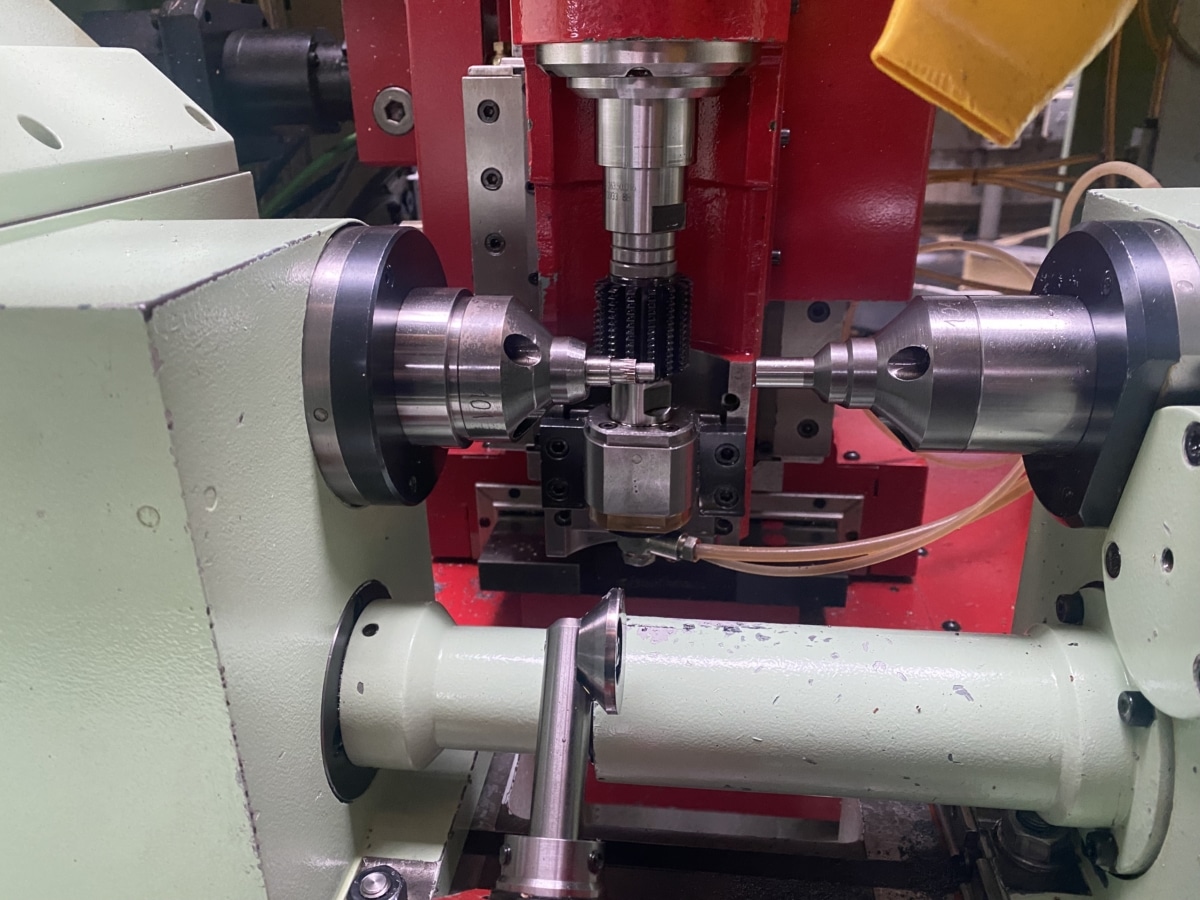

Milling spindle:

The milling spindle is equipped with two sets of two precision bearings at the

front and rear with one set of two conical precision bearings. The tool, with

HSK 32 WIDAFLEX UTS cone, size WDX 32, is manually clamped in the spindle.

manually in the spindle.

Max. Power of the milling motor 1.5 kW /4000 min-1

100 % ED

2.2 kW 4000 min-1

50 % ED

Milling quality:

When using AAA quality milling cutters and corresponding holders quality DIN 6

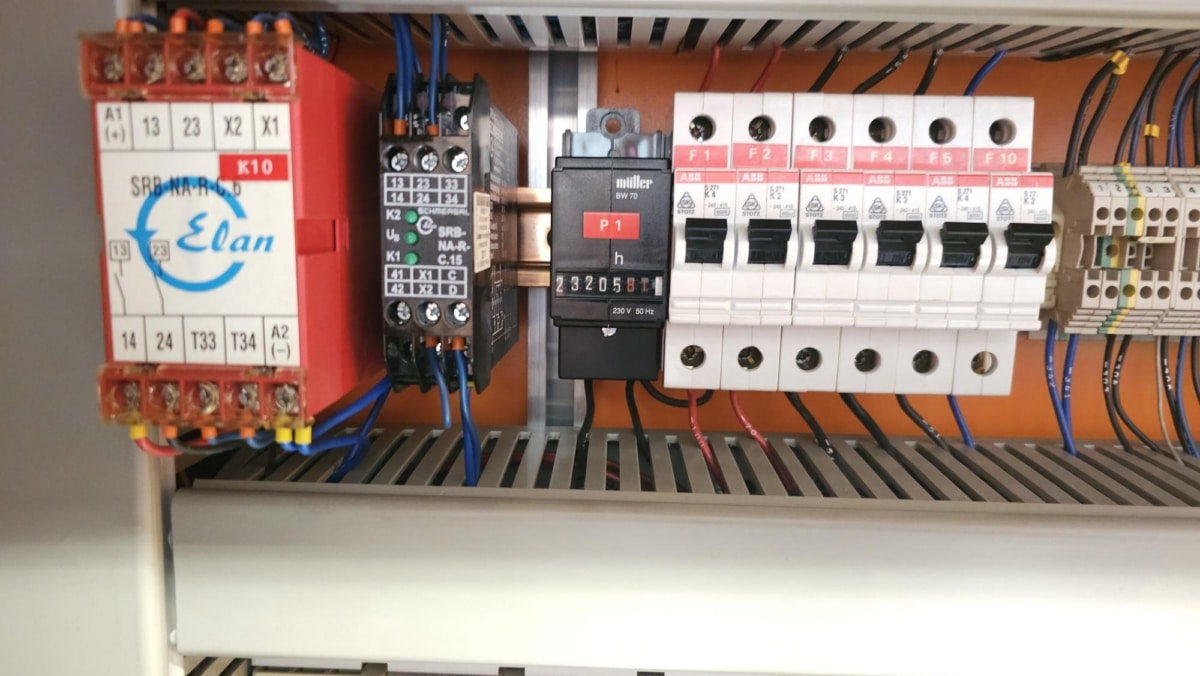

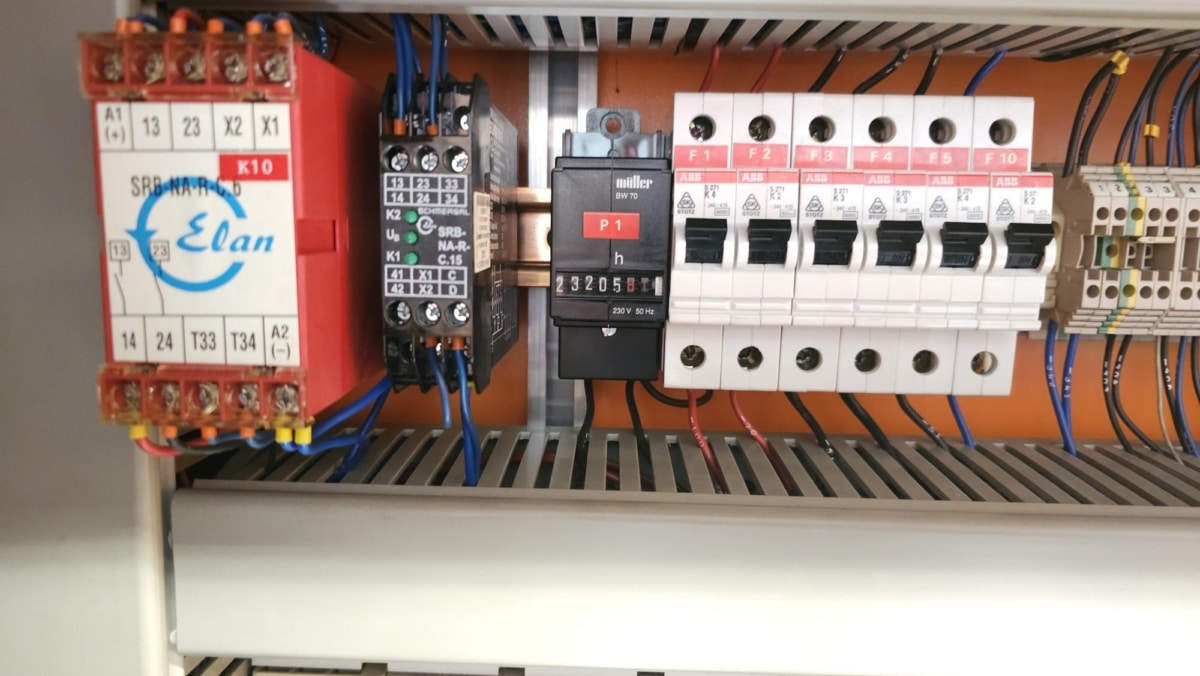

Electrical equipment:

Supply voltage 3x380V, 50 Hz

Max. Voltage 9 KVA

Hydraulic equipment:

Hydraulic oil tank capacity 22 litres

Main circuit pressure 45 bar

Machine dimensions and weight:

Machine weight without loader 3000 kg

Machine dimensions without loader 1730 x 1300 x 1900 mm

Machine weight with loader 3500 kg

Machine dimensions with loader 3000 x 1800 x 2100 mm

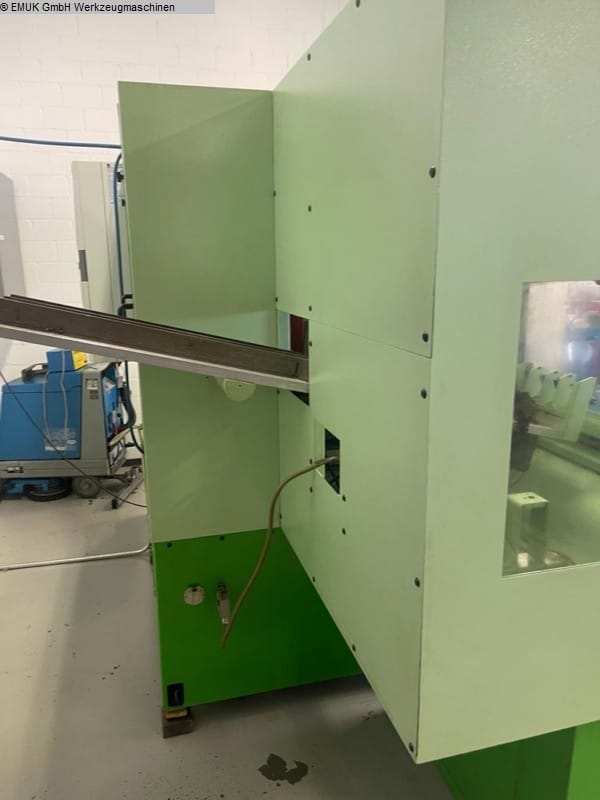

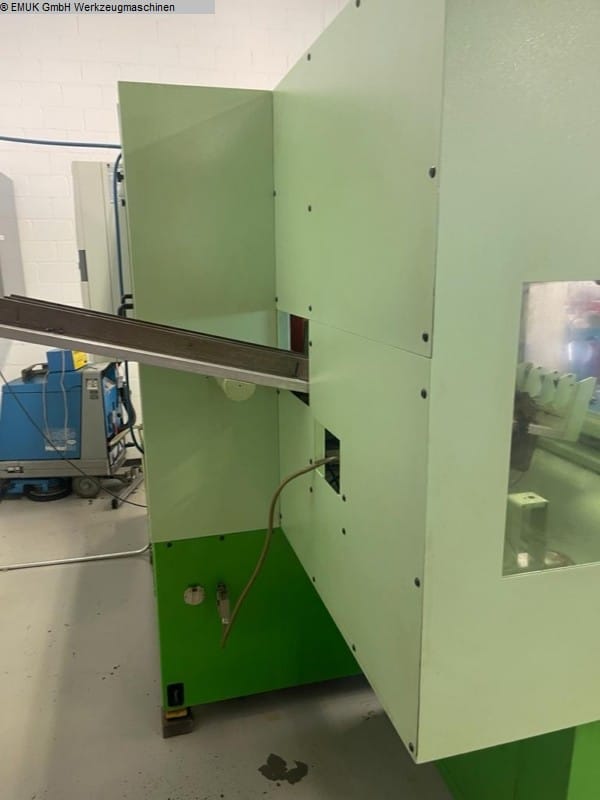

Portal workpiece changer:

Max. permissible dimensions of the workpieces to be changed

workpieces Ø 60 mm

(as an option up to 600 mm) Length 200 mm

Max. permissible dimensions of the transported workpieces Ø 80 mm

when processing with a single gripper (at the expense of loading time). Length

200 mm

Workpiece loader with inclined plane:

This loader enables the automatic loading of max. Ø 80 mm

cylindrical workpieces of any kind, which

roll over the inclined plane one after the other Max. Length 200 mm